Content

Raymond mill

Raymond mill is suitable for the barite, calcite, potassium feldspar, talc, marble, limestone, ceramic, glass and other mohs hardness is not greater than magnitude 7, humidity below 6% of inflammable and explosive mining, chemical industry, building materials, metallurgy and other 280 kinds of materials of powder processing, finished product size adjusted within the range 80-325 mesh.

Raymond mill series models are: 3 r3016 r2615, 3 r2715, 3, 4 r3016, 4 r3216, 5 r4121 etc., should be market development needs the company has introduced a large industrial mill with 6 r and 7 r grinder.

Raymond mill or Raymond mill, Raymond mill, also called Raymond grinding mill, Raymond mill.Mainly by the host, analysis machine, fan, the finished set powder, plumbing, electrical, etc.The host by frame, into the wind volute, the shovel, grinding roller and grinding ring, cover and motor, auxiliary equipment are jaw broken, bucket elevator, electromagnetic vibration feeding machine, electric control cabinet, etc., the user can choose according to site condition flexible.

The working process of the Raymond mill:

Material after jaw broken pieces to the required size, the elevator will material sent to the storage hopper, then through evenly continuous the vibrating feeder will be expected to Raymond mill grinding indoor host, due to the effect when rotating centrifugal force, roller swing outward, press in grinding ring, shovel knife scooping up material to between grinding roller and grinding ring, crushed by roller rolling to achieve.After grinding of powder material with the wind circulation of blower analysis machine for sorting, fine through the coarse material fall back into heavy grinding, qualified fine powder with airflow into the finished product cyclone collection of powder, the powder discharge tube, is the finished product.

Raymond mill performance characteristics:

1. The whole machine for vertical structure, cover an area of an area small, systemic strong, from the rough machining of raw materials to delivery to the flour and final packaging, form an independent production system.

2. Compared with other old milling equipment, sieve rate can be as high as 99%.

3. The host transmission device enclosed gear box and pulley, transmission smooth, reliable operation.

4. Important parts adopt high quality castings and material manufacturing, sophisticated technology, to ensure the durability of the whole equipment.

5. Electrical system adopts centralized control, reasonable selection of advanced high degree of automation.

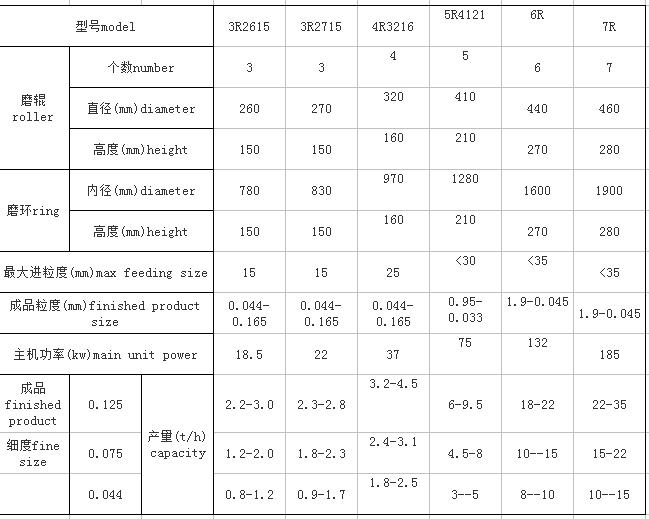

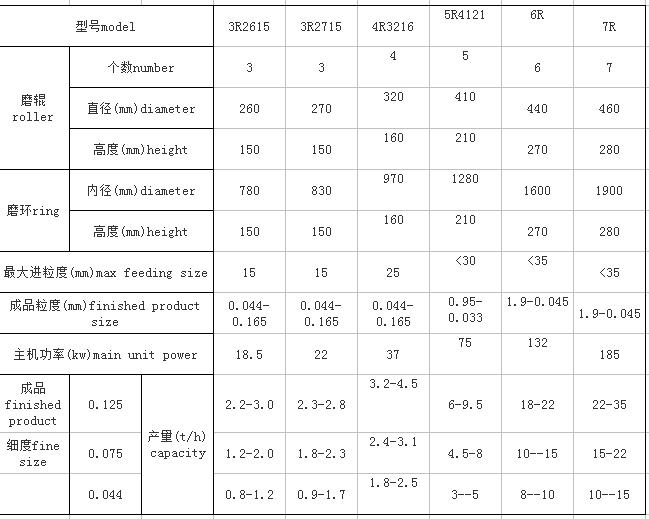

Raymond mill technology parameters: